Mechanical Earth Modelling

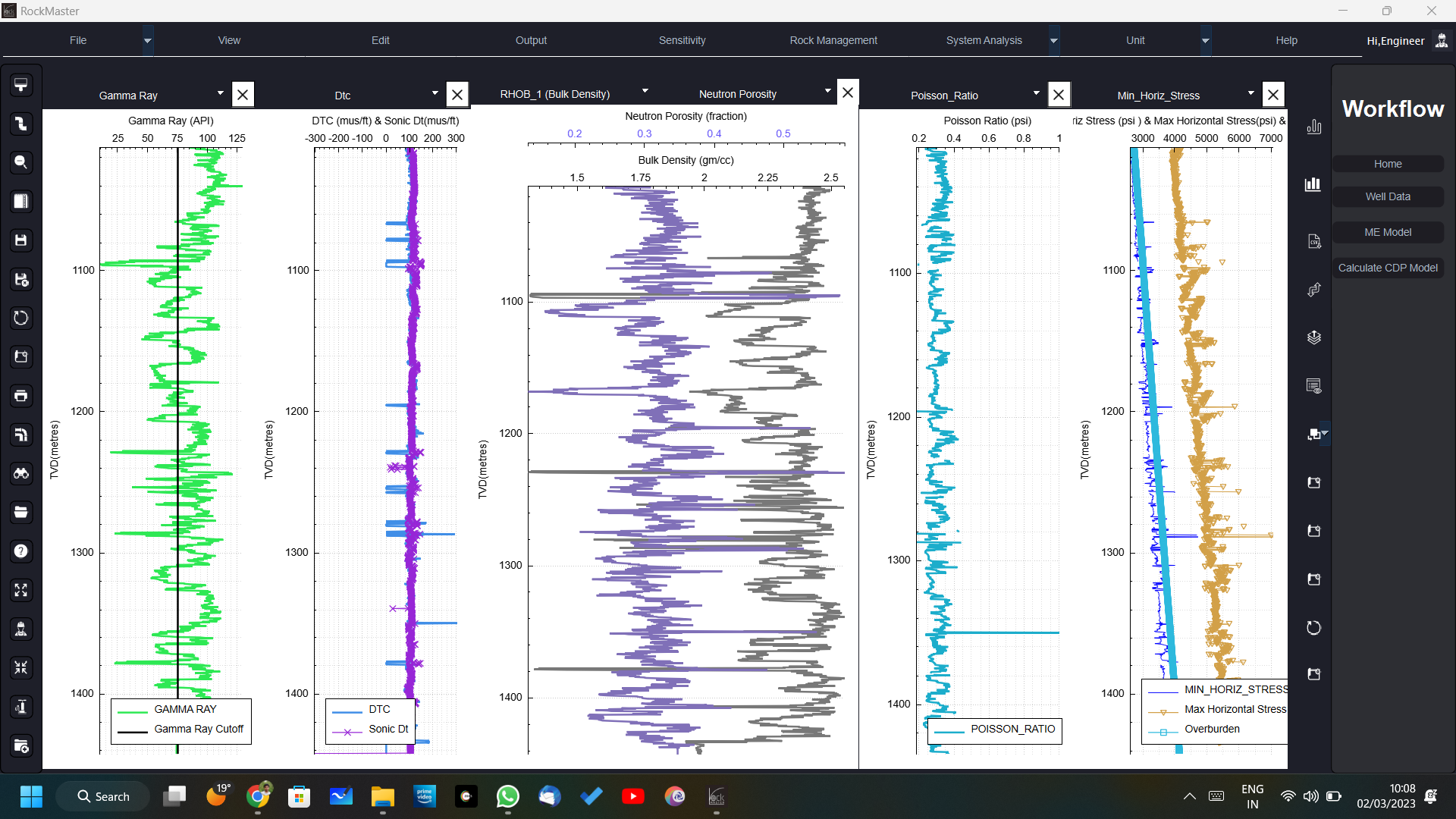

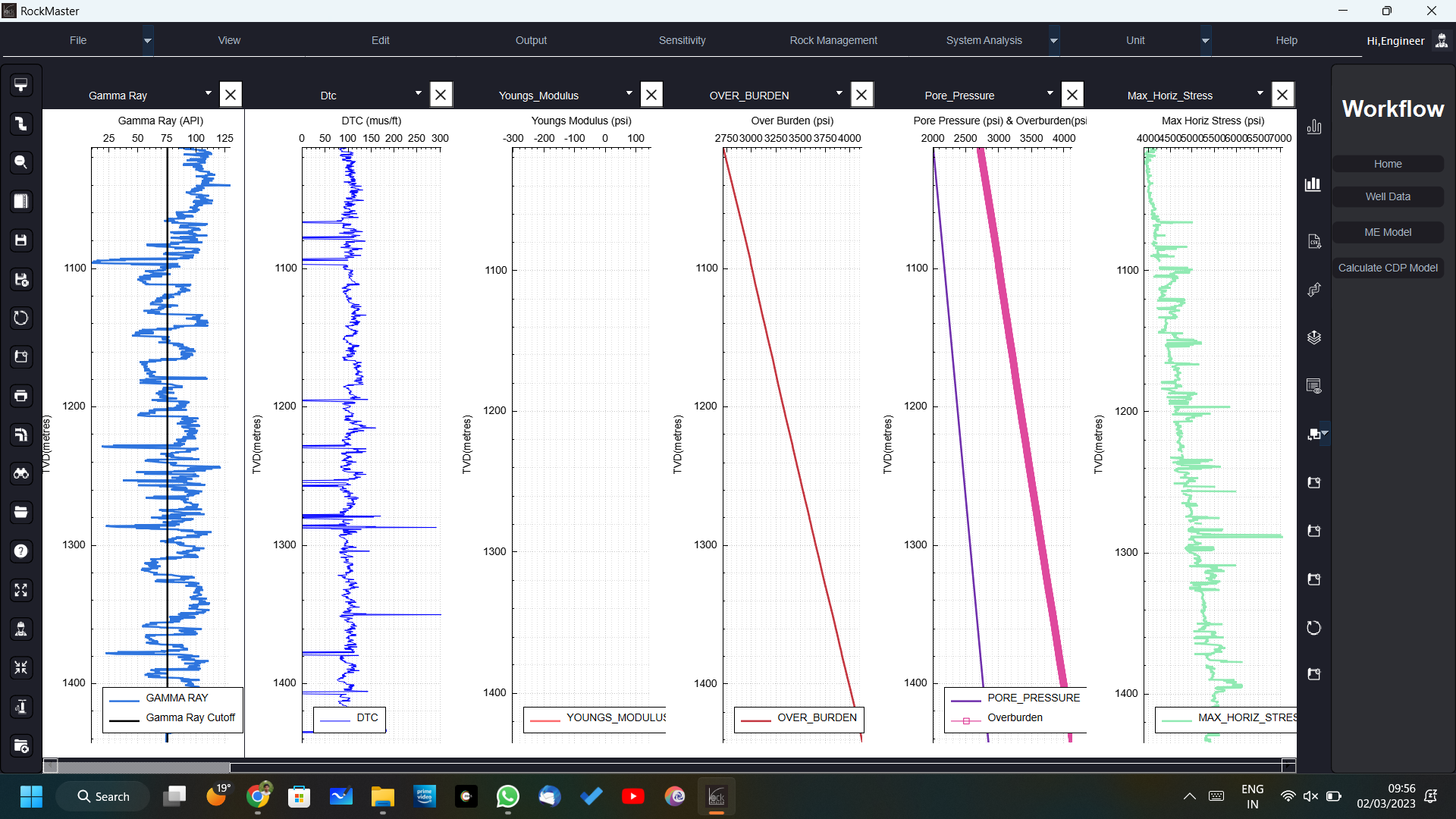

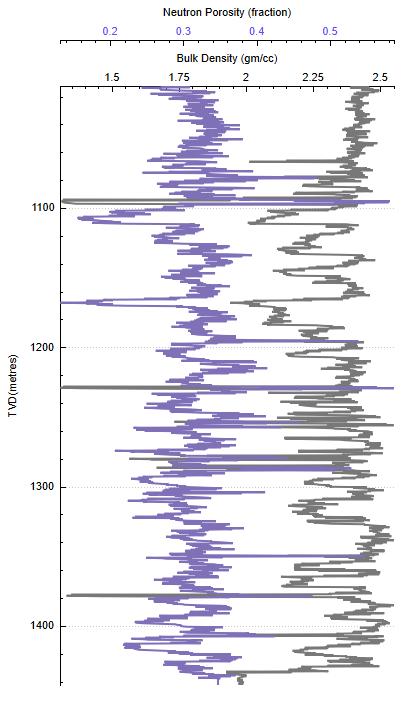

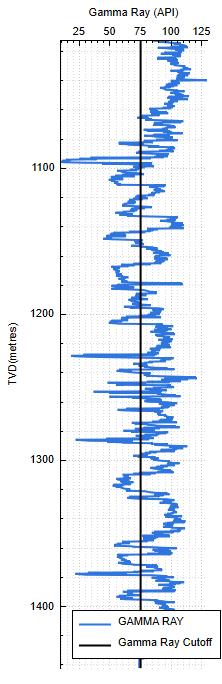

- Preparing mechanical earth models generating rock characteristics Calculation of several rock mechanical properties specifically from basic input log data using several correlations to evaluate Young’s and Bulk Modulus, Poisson’s Ratio, Friction Angle and UCS.

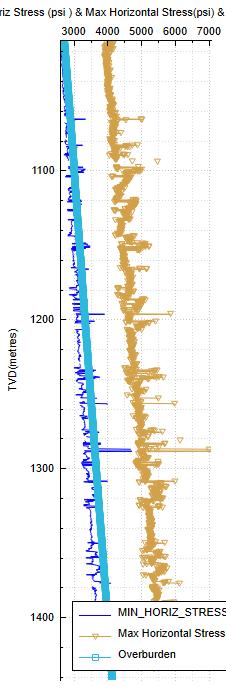

- Estimating stresses (maximum horizontal, minimum horizontal and overburden).

- Generating dynamic and static MEM models.

- Mechanical earth models include the plots of these mechanical properties of rocks as the property v/s depth.

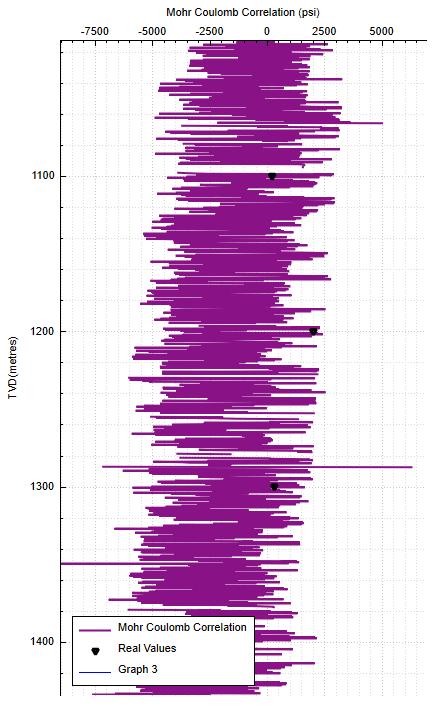

- Calibrating calculated values with real field and lab data.

- The calculated and plotted points can be shifted according to the available real field data and laboratory values obtained.

- Understanding complete rock physics

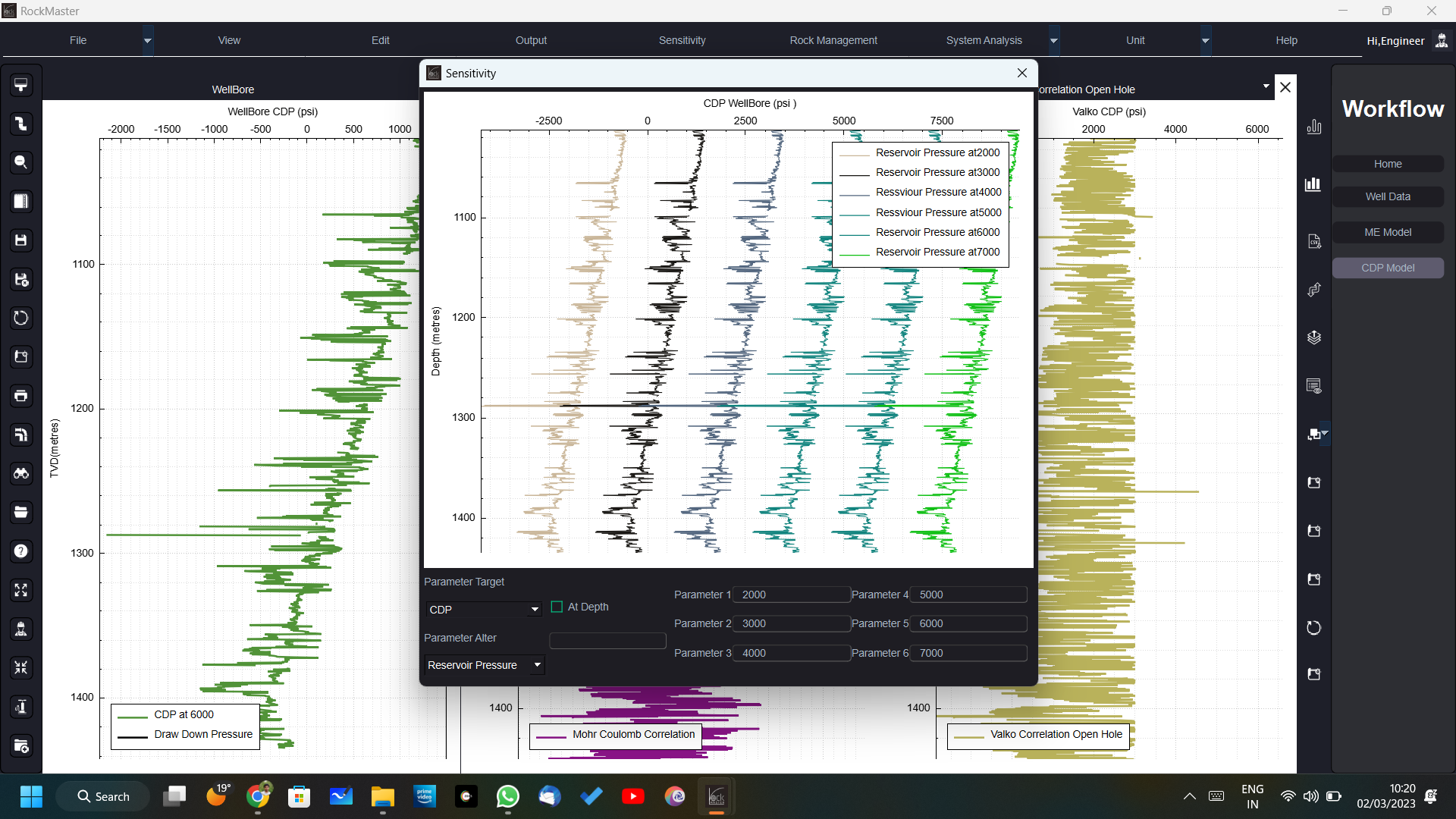

- The complex rock physics can be understood by observing the variations in these properties along the depth and capability of running multiple sensitivities.

Sanding Tendency

-

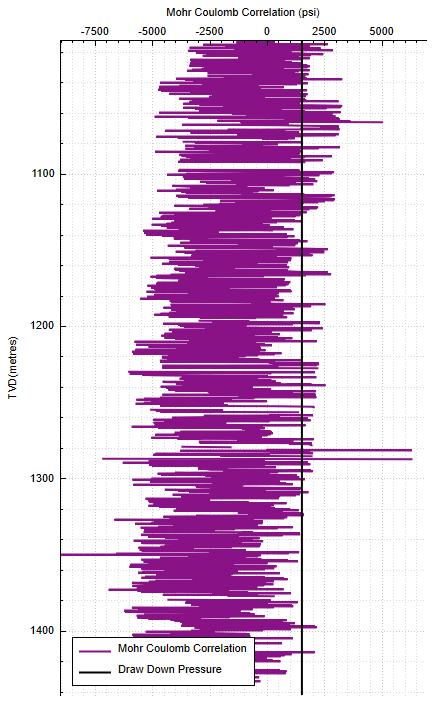

- Generating CDP curves

- There are various correlations currently included for CDP Curve generation both for Open and Cased hole wells.

- Evaluating sand production tendency of wells

- CDP curves facilitate evaluation of sand production tendency of wells Ranking of wells as high, medium and low sanding events.

- Special algorithms within RockMaster application also help to establish sand production tendency of wells, thereby relatively ranking wells using Sand Production Index in terms of sand severity when produced under same conditions.

- Wells can be ranked under high, medium and low sanding event wells for an effective sand management strategy.

- Conditions for approximate catastrophic failures of formation.

- Catastrophic failure conditions can be evaluated to prevent unplanned caving of sand into well and well loss.

- Accurate modelling of CDP and real field calibration cum prediction for field life.

During the entire field life, the real field value of CDP at a depth can be entered and this can be calibrated with the calculated one at that depth. This change changes the already designed model in terms for better future prediction and validation.

Field Life Sand Modelling

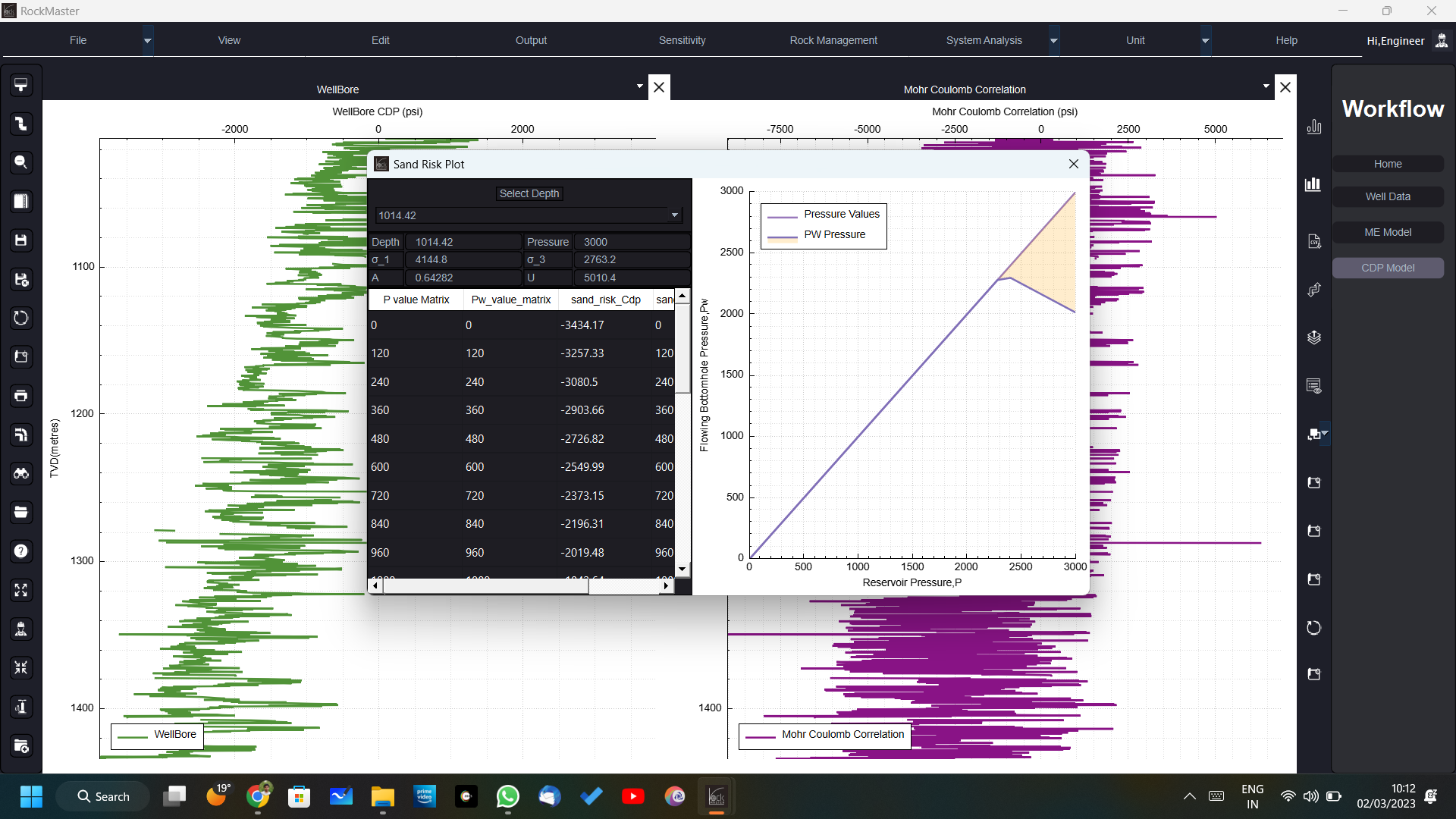

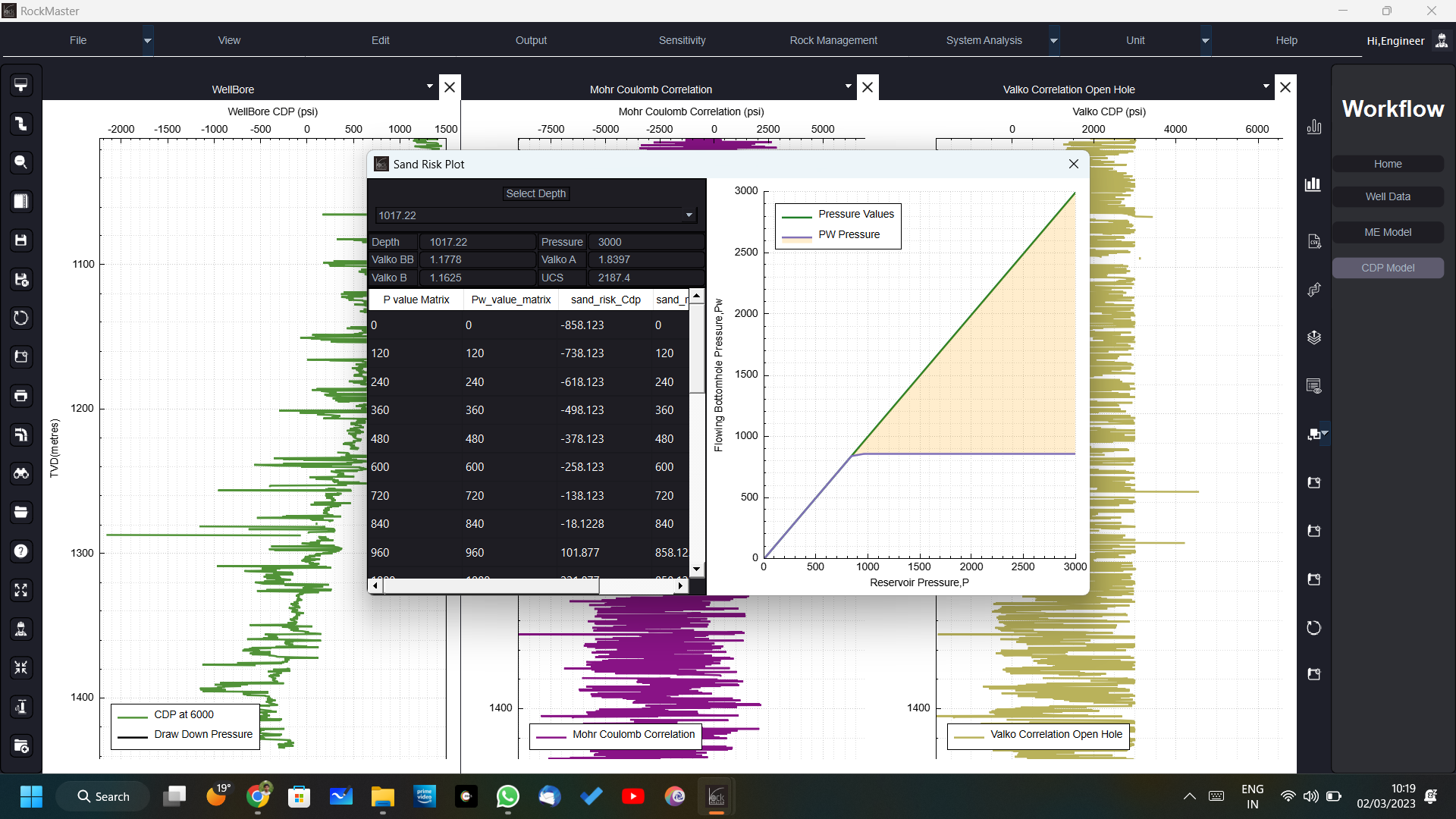

- Reservoir pressure-based sand production

- Sensitivity analysis of the CDP calculated by varying the parameters involved in calculating CDP curve.

- Reservoir pressure is such a parameter which influences CDP values. For different reservoir pressures possible in a formation for a well, the CDP curves will be generated.

- Wellbore stability diagrams and CDP triangles

- An outstanding analysis wherein the stability triangle is generated at every depth to identify the sand free zones and risk zones for combinations of reservoir pressure and bottomhole pressure.

- Effect of sanding due to water cut, higher drawdown, gas production and other parameters

- Due to encroachment of free gas and formation water, the sanding tendencies are estimated.

As the drawdown exceeds the critical value designated by the CDP model, sanding may occur.

Sand Management Strategy

-

- Defining sand management strategy for long tern field development

- Possible strategies for effective sand management over the field life will be provided depending on the well sanding condition, rank and other factors.

- Long term support can be provided.

- Defining selective and add perforation selection and risks

- To reduce further sanding, perforation strategy is provided by estimating the perforation selection (adding).

- The risks involved will also be designated.

- Ensuring wellbore stability and orientation for stable and non-sand production with hydrocarbons

- To ensure non-sand production and maximize hydrocarbon recovery, wellbore stability analysis will be performed and orientation of the wellbore is decided and controlled.

- Defining sand control options on basis of best economics

- Several sand control methods available in the industry are performing well in controlling sand production during the life of a well.

- Some methods include installing some special tubulars and others involve injecting some fluids to enhance the flow area and obstruct sand entry into the wellbore.

- Depending on the cost involved, the user can select the best method of his choice and design the same to know whether the selected method can be used in field to control sand production.

- Modelling sand consolidation activities

This is an interesting feature where sand consolidation (packing) is modelled to pack the sand and avoid further production which reduces cost and risk.

Long Term Support

- Development of model in RockMaster and regular update

- The developed model will be saved as a file and the user can re-work on it with new field values and other stuff.

- Regular update in time sense can be generated for ease and field validation.

- Delivering of RockMaster in form of license

- For a stipulated time, the license will be provided to the user.

- GOTS sand management experts to advise best sand management strategy

- Amount of sand production with incremental drawdown

- Under the Volumetrics tab, volume of sand production and mass is estimated over the production phase (incremental drawdown).

- Relative sand production from each well in field to identify highest and least sand producing wells within same fields

- This volumes and masses of sand produced will be compared among all the wells of a field.

Identification of highest and least sand producing wells is possible.

Sand Mass Production

- Full field modelling of MEM and sand production for optimized sand management strategy – green and brown fields.

- Efficient connectivity with SandMaster – to provide full field Holistic Solutions