SandMaster

What is SandMaster?

- First Software of its type in Oil & Gas Industry focusing mainly on sand management

- Developed on a patented workflow, SandMaster is all about Sand Management Systems & Tools for Evaluation of Risk

- A combination of standard & widely used industry correlations with advanced algorithms & programming have been used to generate an entire novel & unique way to manage sand at all levels & catering to all disciplines

- Identifying the Weak-links & identifying Risk Envelopes for Erosion, Deposition & Handling risks within a facility for components affected by sand production

Unlock current challenges in Sand Management

- Decision making whether to manage sand at surface or downhole during greenfield FDP & facility designing and/or brownfield rejuvenation phases

- Estimating component life on basis of calculated risks and erosion rate

- Optimum sand production limit within which facilities can be operated without any HSE risk

Highlights of the Main features

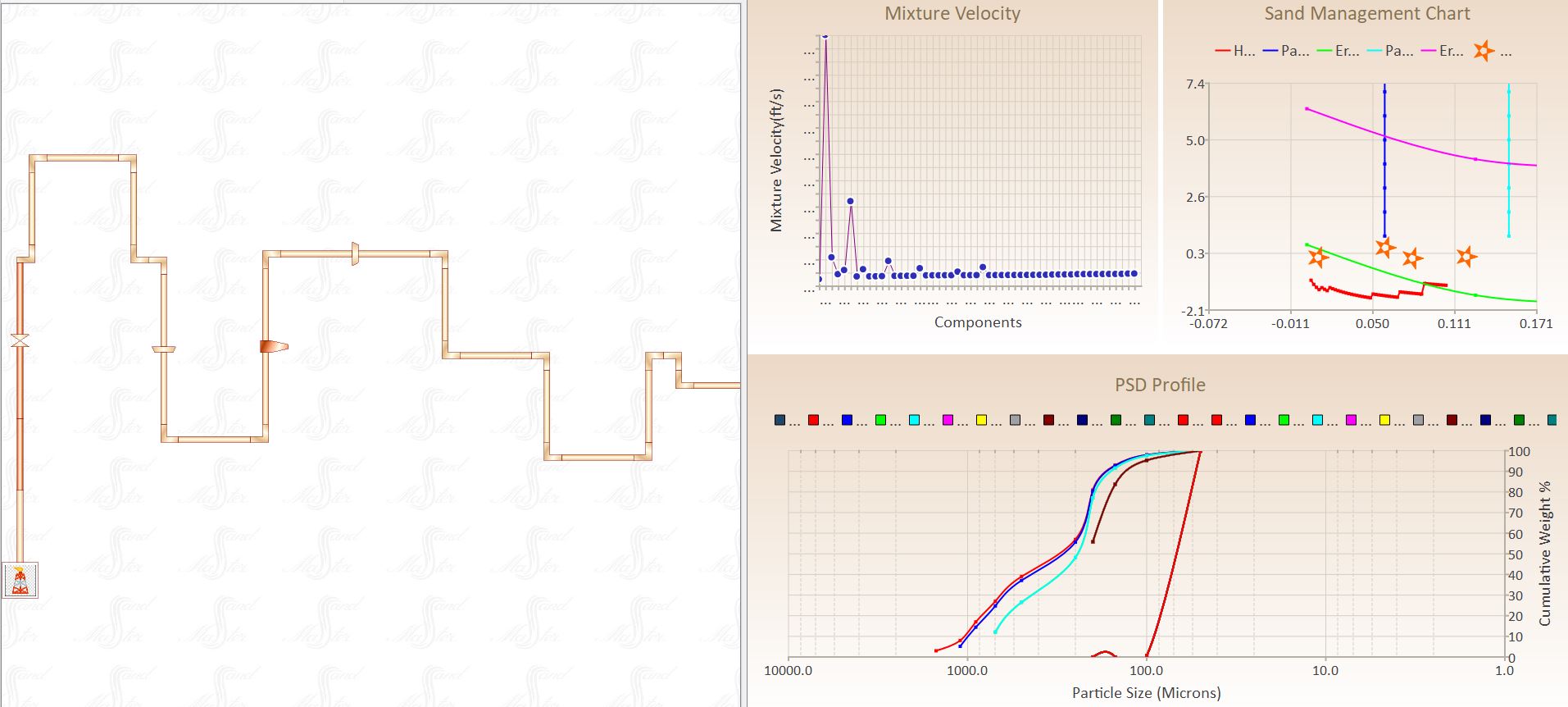

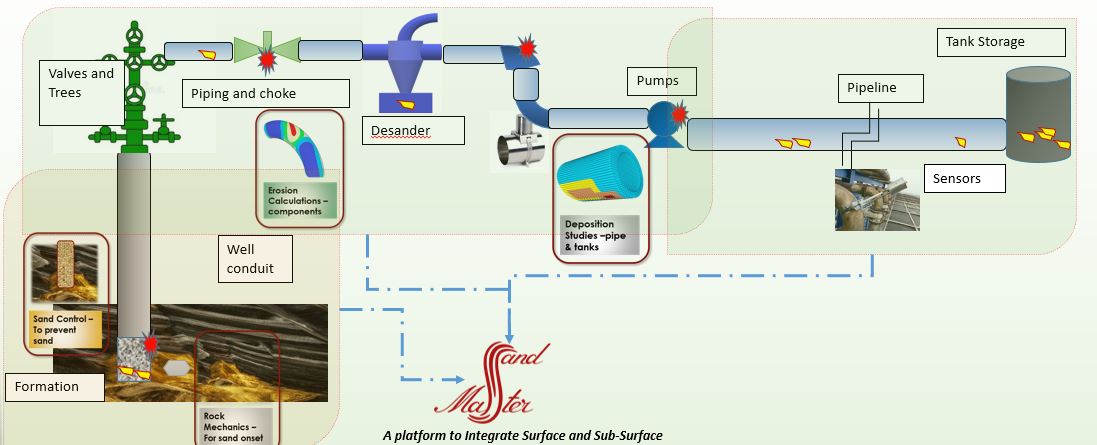

Modelling entire facility from wellbore to surface

- Development of entire facility : The software has the capability to develop an entire facility right from a sub-surface well-bore up till topside facilities & pipelines in a single model. The block format of preparing the facility is an easy-to-use interface and helps in developing the entire model of any number of

- Sand Mapping : As the facility is modelled and flow parameters are included, a sand mapping i.e. sand flow parameters like sand concentration, sand mass rate, velocity of individual particles and even deposition rate can be obtained for every single component being defined.

- Handling Gas injection and separation : For a multiphase flow, expansion of gas determines the velocity of system as well as flow regime. Within SandMaster a special feature of including and excluding gas to and from the system is incorporated.This provides a flexibility of simulating injection of gas and operation of a separator efficiently.

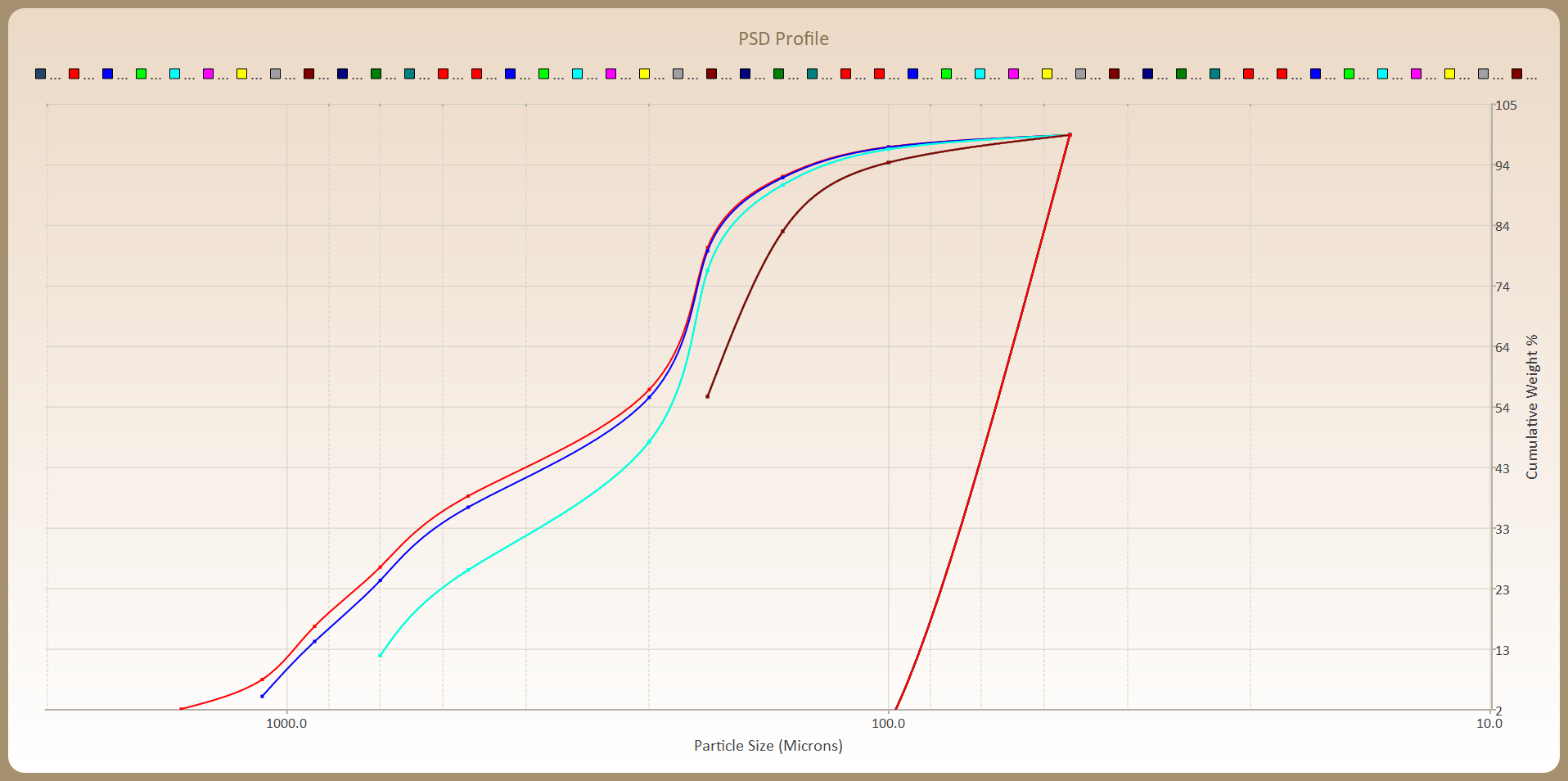

- Particle Size Distribution profile : SandMaster’s unique feature of providing a complete PSD profile after separation at each and every component, takes the experience of sand management & its application to a completely new level.

Simulation of Solids related risks

- Deposition Risk : Deposition of sand whether downhole or at topside is one of the biggest challenges. With state-of-the-art algorithms and multiple deposition models, SandMaster brings a unique feature of simulating solid deposition for individual particle sizes – in annulus, casing, production tubing, surface pipelines & Separators/vessels.

- Corrosion – Erosion : Incorporating the corrosion correlations and ability to evaluate erosion-corrosion combined analysis brings in a unique way to model this concept. Whether its an erosion dominated corrosion or corrosion dominated erosion can be easily detected.

- Sand Handling Risk : This feature is an extension of Deposition risk evaluation where user can perform time-based calculations to optimize removal/flushing of filled up solids from any location whether downhole or top-side. Ex-Coiled tubing Cleanouts or Separator/desander flushing scheules

- Erosion risk : Once the facility is generated, sand flow related risks like erosion in pipes, bends, chokes & pumps can be highlighted along with wall loss predictions to manage facilities.

A unique blend of Algorithms & Calculations

- Scatter point Calibration for Erosion : It is at times challenge to calibrate, or history match the output of erosion or deposition due to different flow conditions. A special feature of application is the ability to provide the average calibration factor for a component if there are multiple such component or operating in entire facility at different flow environments. A similar logic can be used to determine the calibration factors of a particular component over a period of time.

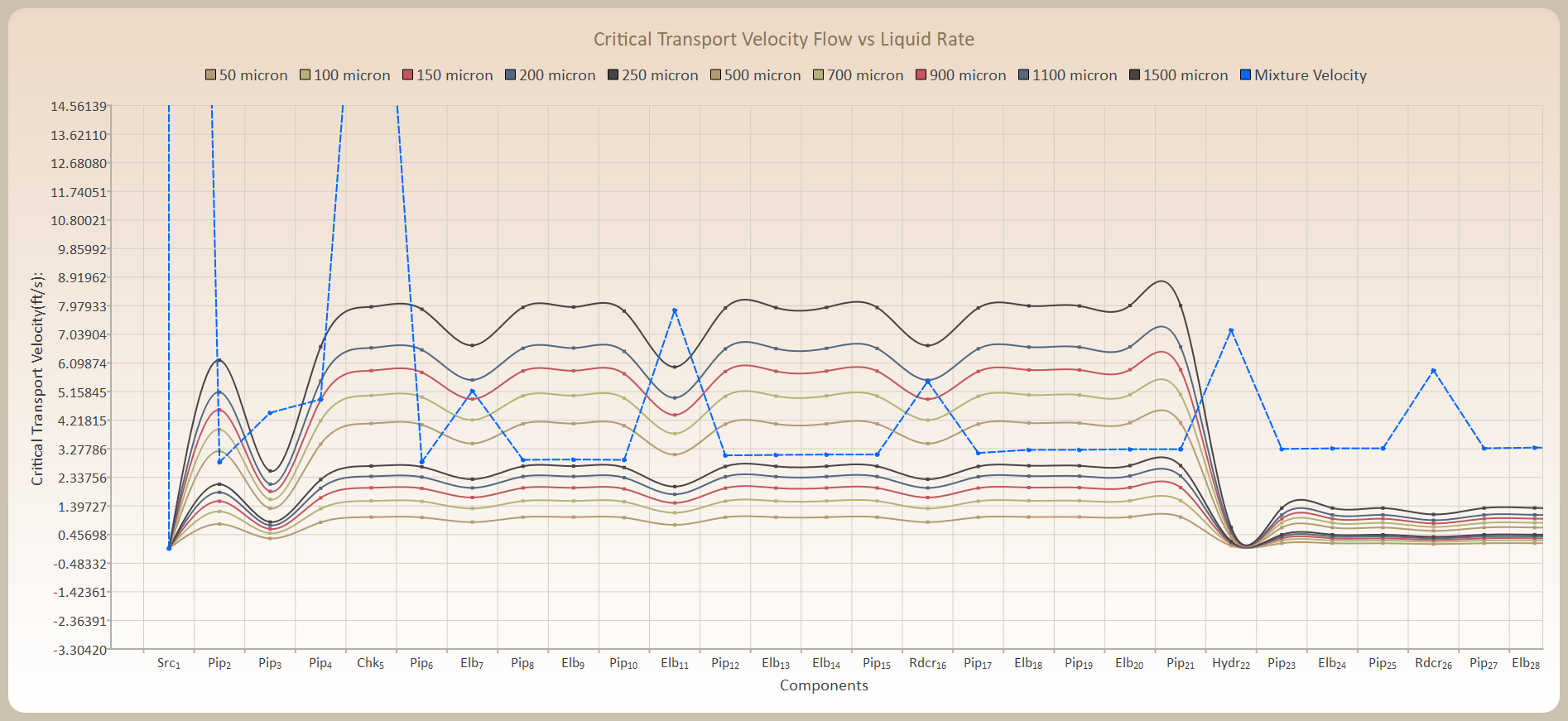

- Critical Transport velocity : The software enables in calculating critical transport velocity via various methods ensuring every single particle size is count and is calculated

- Operating Envelope : The entire facility once modelled can be diagnosed for the various risks in individual platform and an interactive patented algorithm-based Sand Management Chart can be prepared as an operating envelope for the entire facility.

- Calibration of models : With calibration of models with true values, SandMaster provides a facility to not only history match the data bit ability to predict the data for a better risk

Critical component design & facility Integrity

- Component Life and MAWT : Each component is characterized with feature of calculating the minimum allowable wall thickness on basis of working pressure and conditions. This helps in further evaluating to the end user, the duration of component life. This enables user to identify the weak links within the system &components which can be highlighted at first instance

- Data Analytics : Development of a strong back-end data base for component life due to metal loss, erosion rates, unique algorithms on deposition and sand management risks/production uplift opportunities. This not only establishes trends on the basis of flow regimes, but also enables organizations to develop their own factors and modified correlations suited to specific fields and platforms.

- Choke Management Plan : With multiple ways to predict choke erosion and choke health status, the software provides the ability for any operator / service provider to develop a robust choke management plan.

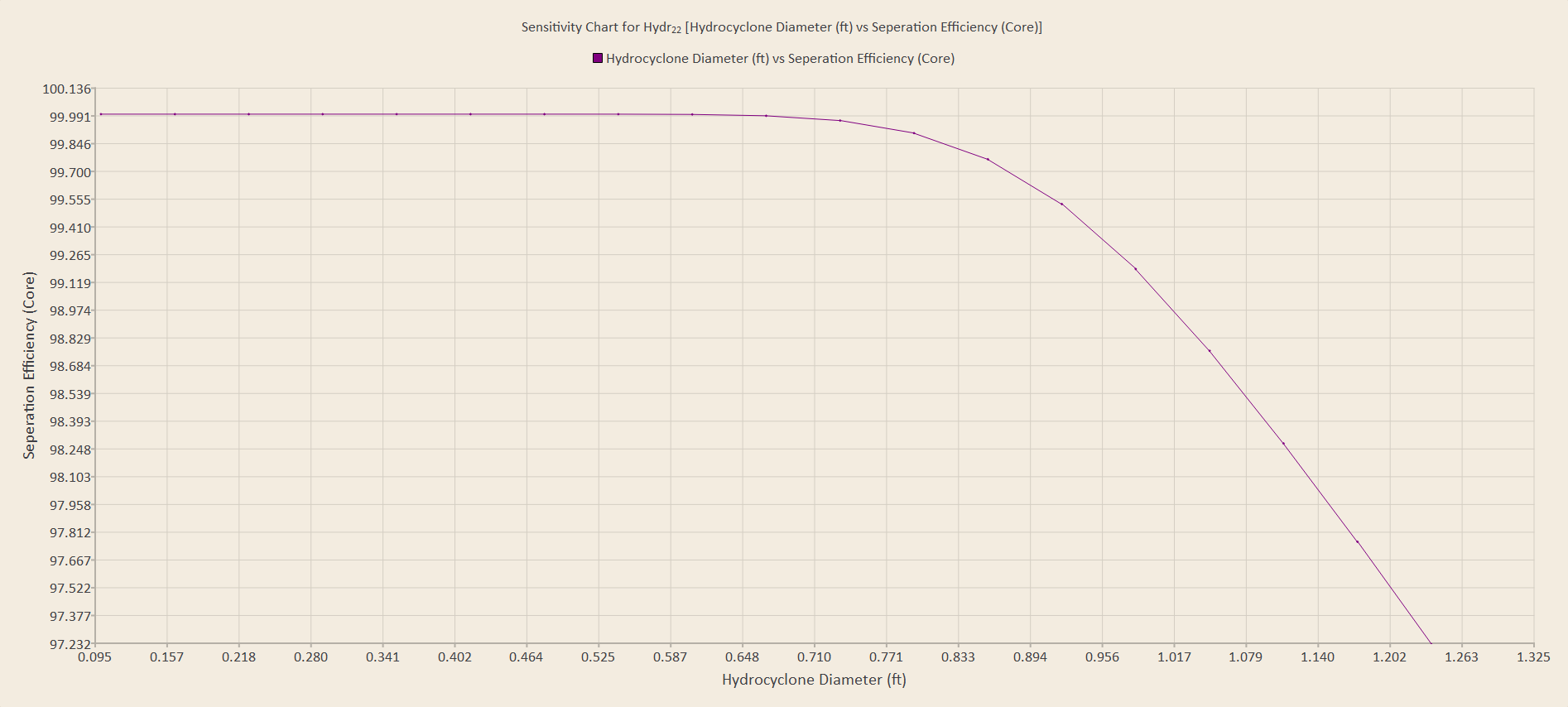

- Hydro-cyclone design : Software incorporates inclusion of hydro-cyclone i.e. solid separation systems with sensitivities and separation logics to provide decision making on hydro-cyclone. User can play with various geometries of hydro-cyclone to evaluate cut diameter and thereby separation efficiencies.